Water Air Valves

Sierra water air valve series 6400- PP Are Hydromechanical devices designed to automatically release or admit air during pipeline filling, draining, or operation of a water pipeline or system. The safe operation and efficiency of a pipeline are dependent on the continual removal of air from the pipeline.

Sierra Air Valves Model 6400-PP functions

- Discharge large volumes of the pipeline to atmosphere during pipe filling. (Atmospheric Function)

- Entrance of large volumes of air to the pipeline during pipeline drainage during washout conditions. (Atmospheric Function)

- Discharge small volumes of air during pipe-line operation under pressure, preventing accumulation and formation of air-pockets during pipe-line operation. (Pressurized Function)

- Limiting the air flow velocity during discharge conditions when uncontrolled or high velocity pipeline filling, this causes an air-cushion in the pipeline, lowering high speed of water running which follows air, reducing the risk of induced impact (surge) and maintain safe closure of the main float.

Design Features

- Advanced design with simple mechanism, strong float to prevent cracking during sudden water hammer and quick closure prevention.

- Single chamber full bore body in ductile cast iron, PN 25 bar rated

- Aerokinetic mechanism to resist blow shut under higher air velocity even up to sonic velocity of air.

- No arms or levers to prevent vibrating, bending, direct closure of the float

- Smooth guide outside of the float, keep float moving in specified guide rail.

- Fully fusion epoxy coated inside and outside of valve body for long term services.

- Maintenance can be easily performed from the top without removing the air valve from the pipe.

- Mobile block consists of a cylindrical polypropylene float assembly. float components joined together accurately to avoid deformations and ensure a great sliding precision inside the body.

Features of polypropylene: using PP (Polypropylene) material in water valves offers several distinct advantages. Firstly, PP has a lower density than water, allowing the valve to remain buoyant, ensuring efficient water flow control even in submerged conditions. Additionally, PP’s inherent durability makes these valves highly resistant to corrosion, chemical degradation, and wear over time, resulting in a longer operational lifespan. This combination of low density and exceptional durability positions PP as an optimal choice for water valves, ensuring both effective functionality and extended service life.

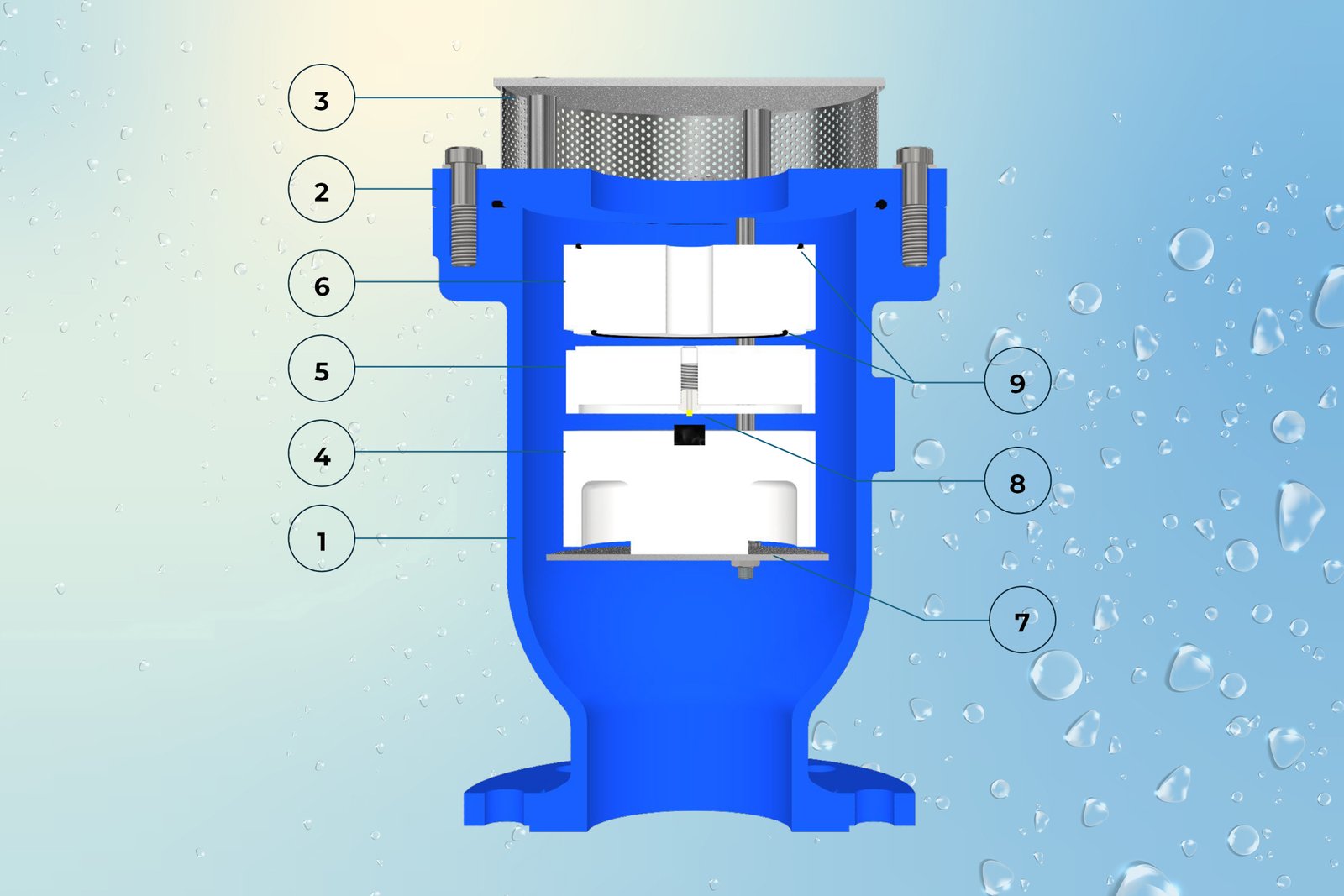

Material Standards

1,2. Body, Cover —— Ductile Iron EN-GJS-500/7 Or Ductile Iron EN-GJS-400/12

3. Screen —— Stainless Steel Grade 304

4,5,6. Floats —— Polypropylene

7. Float Guiding Mechanism —— Stainless Steel Grade 304

8. Small orifice —— Stainless Steel Grade 304

9. Float Sealing —— EPDM Rubber